The Client

Quantum Profile Systems, based in Oldham, produce PVC extruded profiles for the building and construction sectors. These include stair nosings, PVC trim and flooring transitions for commercial, public and shared buildings, including stadiums and hospitals. Their Lean, Green, Safe and Clean principles create customer value and quality.

Quantum Profile Systems became aware of Starfish Construction following an online search, and after reviewing our previous projects, we were invited to take part in the tender process. Quantum Profile Systems and their civil engineers, The Francis Bradshaw Partnership, reviewed our tender submission and were confident that Starfish Construction was the best fit for the project based on cost and experience.

The Project

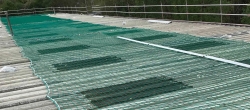

The roof of the manufacturing facility was in a significant state of disrepair. In particular, there was substantial cut-edge corrosion, which had caused leaks in several areas. The scope of work involved installing sacrificial netting, 200 mm insulation quilting, a new profile metal roof clad over the existing roof, and a replacement gutter system.

Quantum Profile Systems wanted to add solar PV to the redundant roof space, which meant we would need to consider the additional weight. We engaged the material manufacturers in the design process to ensure the best system. As part of our Diagnose, Design, and Deliver methodology, we conducted a technical drone survey of the roof area and a full site measure.

- Increased loading on the roof to allow for solar panels

- Increased usable roof space

- 20-year material warranty

- MEWP surveys to measure the roof

- The site was fully operational throughout the project

- Completed four weeks ahead of schedule.

£360,000

Value

7 Weeks

Duration

4,237 m2

Area

Challenges and Solutions

The project had several challenges. Working closely with the structural engineers was essential to increase the loading on the new roof to allow for installing solar panels after the project was complete. As Quantum Profile Systems would continue to be fully operational throughout the works, we installed scaffold access towers and full roof edge protection, allowing them unrestricted access to the loading bay throughout the project.

Our site manager coordinated daily with the Quantum Profile Systems management team to help plan each project stage and allow their staff and suppliers to move safely around the factory, car park and loading bay.

Outcome

Starfish Construction completed the project four weeks ahead of schedule. The new roof now has an increased usable surface area to maximise the installation of solar panels. The roof insulation will help retain heat and improve the efficiency of the new solar system once installed.

The client was pleased with our work ethic and reporting process throughout the project. The manufacturer’s 20-year material guarantee will offer peace of mind and reduce maintenance.

It was important for us to have the right contractor on site. One that took the right approach to safety and would also allow us to continue operations to service our customers. Overall, it was a seamless and safe experience. We were impressed with our initial research into Starfish Construction, and after the tender process, we were confident they would deliver a successful project.

Simon Crossley, Managing Director, Quantum Profile Systems Ltd